How a chainsaw oil pump works

How a chainsaw oil pump works

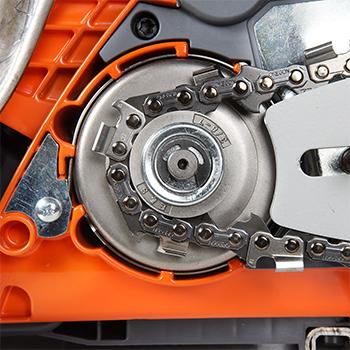

The oil pump is part of the chainsaw lubrication system, which consists of:

-

Piston pump.

-

Tank with vent, to balance the inside and outside pressure, and a filter that traps impurities.

-

Oil outlet hole on the guide bar.

But how does a chainsaw oil pump work? The crankshaft drives the pump, which draws oil from the tank and pushes it onto the guide bar via the outlet hole. The movement of the chain then distributes the oil along the entire length of the guide bar.

Oil pumps dispense lubricant in different ways, and the oil flow can be:

-

Fixed flow, if the lubricant is pumped at a constant rate.

-

Zero flow when idling: in this case the pump is connected to the clutch coupling and only operates when the chain rotates.

-

Adjustable by means of an adjuster screw, which enables the oil dosage to be set based on the length of the guide bar, the wood being cut and the season.

For example, among the various models in the catalogue, the Oleo-Mac GSH 400 basic chainsaw, GS 451 medium-powered chainsaw and GS 651 professional model are equipped with an automatic oil pump that is calibrated to guarantee adequate lubrication in all working conditions, but which is also adjustable according to your needs, and dispenses no oil when idling.

To ensure a well-oiled guide bar and chain, make sure the tank is full of fresh, good-quality lubricant and regularly clean the chainsaw’s oil pump. But before cleaning it, check whether the chainsaw oil pump is working properly first. Simply point the chainsaw guide bar down towards a dry, uniform surface, and throttle to medium speed for a few seconds. If everything is in order, you will see a stream of tiny oil droplets fall to the ground from the moving chain.

How to clean a chainsaw oil pump

Did your chainsaw fail the lubrication test? It might just be a cleanliness issue, otherwise the cause could a worn or damaged oil pump component. In the latter case, the pump must be replaced.

So, below we explain how to clean an oil pump:

-

Keep the guide bar and chain clean: you can degrease them with diesel, petrol or a specific detergent, including concentrated degreaser supplied by Oleo-Mac.

-

Clear any sawdust, congealed lubricant and dirt out of the oil outlet hole on the guide bar.

-

Keep the oil pump tank clean: even if it is equipped with a filter, wipe away all dirt around the cap before refuelling.

-

Regularly check and clean the tank vent and the filter itself.

-

If the chainsaw has been out of action for a long time and the chain oil has solidified in the tank, rinse it out with diesel or petrol.

-

Pour some petrol (or diesel) in the oil tank and run the chainsaw for a while to flush the pump and its circuit.

-

Empty the tank and fill it with chain oil: but if you plan not to use the chainsaw for a long time, leave the tank empty.

If all of the above is not enough, you may need to remove the oil pump from the chainsaw and clean it by hand, for example by letting it soak in diesel before drying and reassembling it.

Do you want to replace your chainsaw with a new model? You can find some useful suggestions in our article on how to choose a chainsaw to match your needs.